< Previous | Contents | Next >

Section 2 Test Specimens and Testing Procedures

201. General

1. Test specimens and mechanical testing procedures specified in this Chapter for welding procedure qualification tests, welders and qualification tests, approval test and periodical inspection of welding consumables are to comply with the requirements in this Section.

2. Where specimens and mechanical testing procedures differing from those prescribed in this Section are used, they are to be approved by the Society.

202. Selection of test specimens

1. Test specimens are to be selected according to respective requirements in each Section.

2. Except where otherwise specified or agreed with the Surveyor, test specimens are not to be de- tached from the test assembly until having been stamped by the Surveyor.

3. If test specimens are cut from test assemblies by flame cutting or shearing, a reasonable margine is required to enable sufficient material to be removed from the cut edges during final machining.

4. The preparation of test specimens is to be done in such a manner that test specimens are not sub- jected to any significant cold straining or heating.

5. If any test specimen shows defective machining or defects having no relation to the substantial na- ture, it may be discarded and substituted by another test specimen.

203. Size and dimensions of test specimens

1. Tensile test specimens

(1) Tensile test specimens are to be of size and dimensions given in Table 2.2.1, and the both ends of the test specimen may be machined to such a shape as to fit the holder of the testing machine.

(2) The upper and lower surfaces of weld are to be filed, ground or machined flush with the sur- face of plate.

(3) When the capacity of the available testing machine does not permit testing the full thickness

specimen, two or more thinner than full thickness specimens may be prepared by cutting the full thickness specimens into section, each of which is to meet the requirements.

2. Bend test specimens

(1) Bend test specimens are to be of size and dimensions given in Table 2.2.2 according to the kind of test assemblies.

(2) Where the thickness of test assemblies is greater than the thickness of the bend test specimen

prescribed in Table 2.2.2, the face bend or root bend specimen may be machined on its com- pression side.

(3) Reinforcements and back straps are to be machined flush with base metal.

3. Impact test specimens

Impact test specimens are to be charpy V-notch impact test specimens specified in Ch 1, 202. 3

and to be of size and dimensions given in Fig 2.1.3, Tables 2.1.3 and 2.1.4.

4. Confirmation for test specimens

The size and dimensions of test specimens are to be carefully inspected and verified by suitable means before testing.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Table 2.2.1 Size and Dimensions of Tensile Test Specimens (Unit : mm)

Type | Size of specimen | Dimensions | Intended for | ||

R 14A |

| = 10 = 50 = 55 10 Alternatively. = 5 = 12 | Deposited metal tensile test Longitudinal tensile test | ||

R 10 | = 12 | Deposited | metal | tensile | |

= 6.0 | |||||

= 24 | |||||

= 32 | |||||

6 | |||||

test(Welding consumables | |||||

= 19~25 | |||||

for stainless steel) | |||||

= 12.5 | |||||

= 50 | |||||

= 60 | |||||

15 | |||||

R 2A |

| = | Butt weld tensile test for plate | ||

= 12 ( = 25 ( = B + 60 | 2) 2) | ||||

25 | |||||

R 2B |

| = | Butt weld tensile test for pipe | ||

= 38 ( | 25) | ||||

= 25 ( | 25) | ||||

= + 12 | |||||

50 | |||||

NOTE: The notations used are defined as follows: d : Diameter a : Thickness b : Width | L : Gauge length P : Parallel test length B : Width of weld t : Thickness of material | ||||

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Table 2.2.2 Size and Dimensions of Bend Test Specimens (Unit : mm)

Used for | Type | Size of specimen | Dimensions(1) | Intended for | ||

Welding procedure qualification tests | Face and root bend specimen | RB 1 |

| <1 | 2 = = 30 200 = 1 ~ 2 | Butt weld bend test for plate Longitudinal bend test for plate(2) |

Side bend specimen | RB 2 |

| 12 | Butt weld bend test for plate or pipe | ||

= (3) = 10 200 | ||||||

= 1 ~ 2 | ||||||

Face and root bend specimen | RB 3 |

| 0 9 | Butt weld bend test for pipe | ||

= | ||||||

= + D /10 | ||||||

250 a/6 9 12 = 9 | ||||||

= 40 | ||||||

250 | ||||||

1.5 | ||||||

Approval test and periodical inspection for welding consumables | Face and root bend specimen | RB 4 |

| = = 30 200 1.5 Where the thickness of test assemblies exceeds 25 mm, the thickness of test specimen may be reduced to 25 mm with its surface machined on one side only(com- pression side) | Butt weld bend test | |

Side bend | RB 5 |

| = | Butt weld bend test | ||

= 10 200 | (welding materials for electro-slag and | |||||

1.5 | electro-gas) | |||||

RB 6 | = = 9 200 1.5 | Butt weld bend test (MIG double side, one layer each, butt welding for alumi- nium alloy) | ||||

specimen | ||||||

Welder's | Face and root bend specimen | RB 7 |

| < 12 = = 40 150 1.5 | Butt weld bend test for pipe | |

![]()

![]()

![]()

![]()

![]()

![]()

Table 2.2.2 Size and Dimensions of Bend Test Specimens (Continued) (Unit : mm)

Used for | Type | Size of specimen | Dimensions(1) | Intended for | |||

Welder's qualification test | Side bend specimen | RB8 |

| 12 | = (3) = 9 150 1.5 | Butt weld bend test for plate | |

Face and | RB9 |

| 9.5 | Butt weld | bend | ||

= | |||||||

150 | |||||||

1.5 | |||||||

= 40 | |||||||

( >100) | |||||||

or 25( 100) | |||||||

RB10 |

| > 9.5 | |||||

root bend | |||||||

specimen | |||||||

= 10 | |||||||

150 | |||||||

1.5 | |||||||

= 40 | |||||||

( >100) | |||||||

or 25( 100) | |||||||

test for pipe | |||||||

Side bend specimen | RB11 |

| 12 | ||||

= (3) = 9 150 | |||||||

1.5 | |||||||

NOTES: (1) The following designations are used. : Thickness : Width : Edge radius : External pipe diameter : Thickness of test assembly : Length (2) The specimen also applies to longitudinal bend test for welding consumables for 9 % Ni steel. The width of Specimen, b, is to be B +12 where breath of weld, B , is 26 mm and over. (3) For plates over 40 mm thick, the side bend specimen may be subdivided, each part being at least 20 mm wide and each part may be tested. | |||||||

![]()

204. Mechanical testing procedures

1. Tensile test and impact test

Tensile tests and impact tests are to be carried out in accordance with the procedures prescribed in

Ch 1, 203.

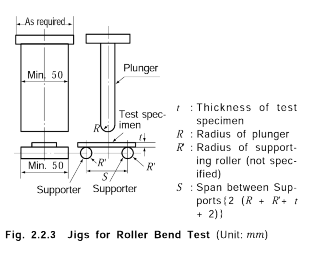

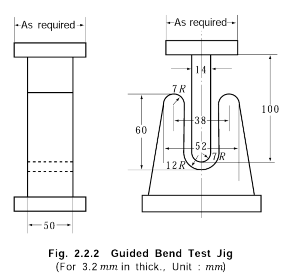

2. Bend test

(1) Except where guided bend tests are required, bend test is roller bend test carried out by the jig

of which the plunger has a bending radius specified in each Section justable for their spans.

(2) Guided bend test jigs are to be as shown in Figs 2.2.1 and 2.2.2.

![]()

(3) Roller bend test jigs are to be as shown in Fig 2.2.3.

with supporting rollers ad-

![]()